TECHNOLOGY

In composites, the details make the difference. BlueWind's operation is built on precision, consistency and continuous improvement.

From 5-axis routers and CNC fiberglass cutting to automated infusion machines and laser tracker systems, our plant runs with the same rigor found in aerospace and automotive industries.

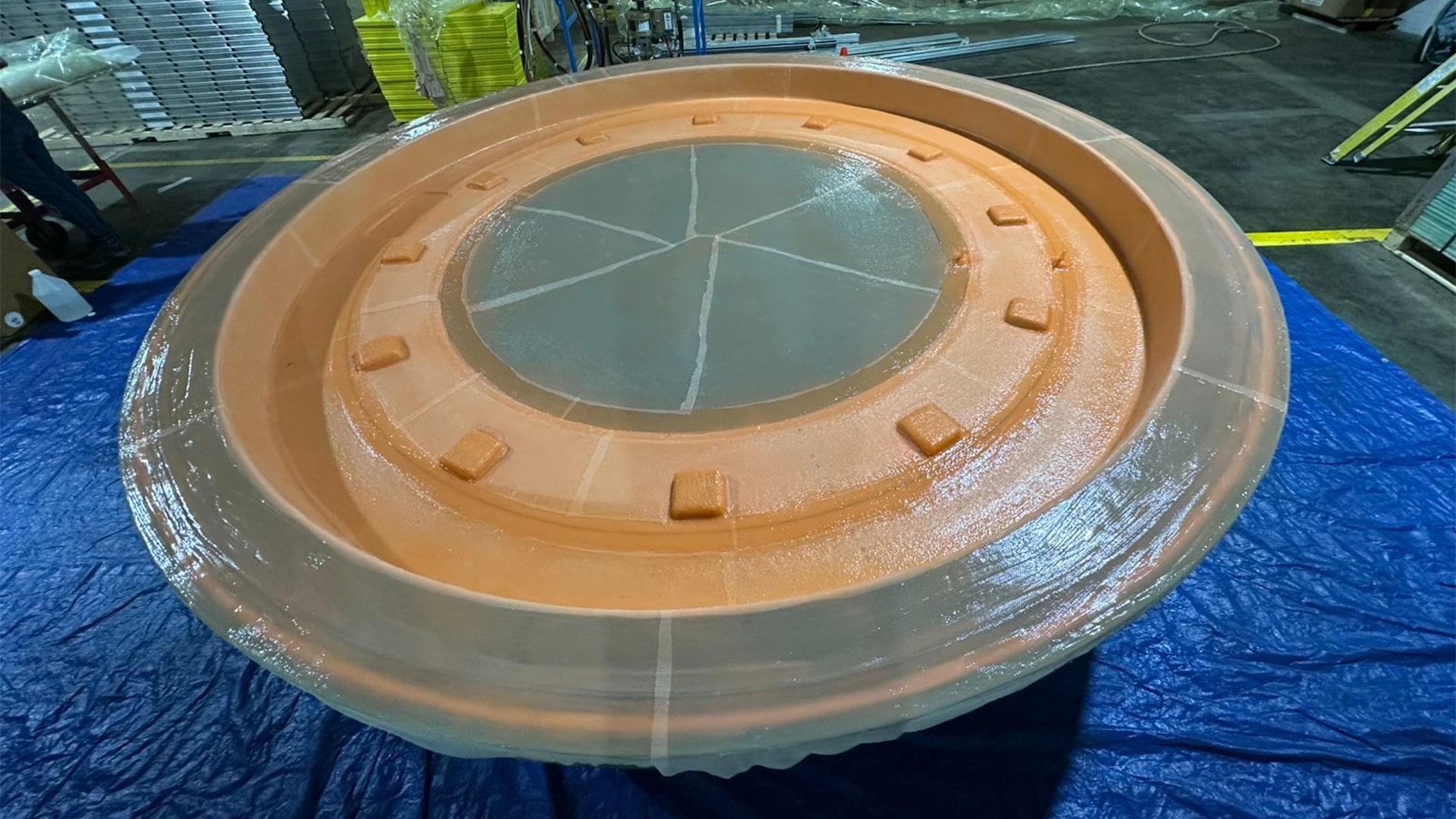

But technology here goes beyond machines. It's about constantly asking how we can improve. That mindset led to silicone skin molding, a reusable tool that replaces disposable consumables, reduces waste, shortens cycle time, and ensures high-quality surfaces.

Each nacelle cover produced with this process avoids unnecessary waste and saves time. Scaled to hundreds of parts, the impact is clear: greater efficiency, stronger sustainability, and better conditions for the people on the shop floor.

At BlueWind, innovation is not an idea on paper.

It's present in every mold, every shift, and every nacelle cover, leaving Pensacola with the consistency our customers expect.